Beyond this, what really sets the THX Video calibration program apart from the ISF is that its instructors are actual professional calibrators who have years and years of experience both in calibrating displays and understanding how the day to day business of calibration actually works versus how it has traditionally been taught to people. Amongst the theory of calibration, many stories are relayed about how the business of calibration actually works and why it is far more than just the physical calibration of a person’s television set. Calibration of the display is not enough and that part will be the easiest work any calibrator does for his client.

The stories of calibrations gone wrong and the lessons learned are just as important if not more important than actually calibrating a display. The class is often described as a class for fighter pilots and taught by ace fighter pilots versus using the engineers that designed the airplanes. The combined calibration experience of the two calibrators totals over twenty years and more than 8,000 displays between them are brought into the class.

All the hard lessons in running a calibration business are also exposed to the students before they delve too far into this calibration world. A student in a recent class had asked us why a lot of the material seemed to have a negative spin. Why would the instructors only talk about the negative attributes of the different TV technologies and the test equipment that is used?

The answer was that no one else in the industry would be telling them about the negative points of any displays or test equipment they would encounter. They would only hear about the positives of everything and we leave that part to the industry and the salesmen. If a student was not sufficiently scared off by how the industry is realistically portrayed in the class environment, then they would be better prepared for what was to come and not surprised when the hype never meets expectation. This goes to another point for how the class operates.

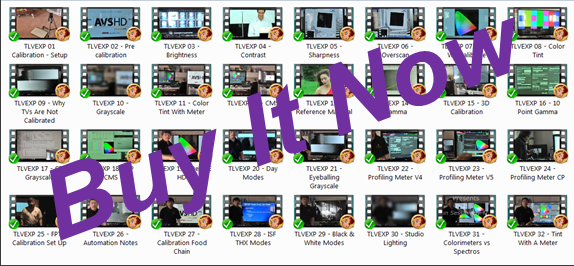

Historically, the students are encouraged to try the different types of hardware and software before making up their mind on what might work best for their business model and budget. (This is the ideal of how the class is supposed to operate, but unfortunately, some choices are more limited and students are exposed to only one software choice and limited hardware choices too, because of economics and personal bias. The class currently uses the Chromapure software as opposed to the Calman software that is also available. A specific software and hardware package for both programs is available to the students. The students should just ask for it.) Fortunately if a student walks into the class with the Calman software, he would not be shunned and would be fully supported with that package.

The aim of the class is not supposed to be selling as much hardware and software as possible onto the students. It is supposed to be teaching the students correctly about the process of calibration and how the business of calibration actually works. This was actually one of the criticisms of the competing class over the years. The class is not about selling a person $10,000+ in equipment and then not supporting them once they get out into the field.

If after taking the class, a person decides that the road to calibration is not the best choice for them, then they would not have dropped $10,000 to learn that hard lesson, but rather just the cost of attending the class which is considerably less than such a crushing capital outlay. One of the primary objectives of the class is to look after what is in the best interests for the student rather than what is best for the instructor’s bank account. If this changes, please keep an eye out for it. Don’t rely on what one instructor says. Get a second opinion and a third.

After the three day class ends, students are required to take two exams, one for each level. In addition to this, 10 calibration reports are required from the students to demonstrate their proficiency in calibration and to ensure that they actually buy software and hardware. Within the class itself, no one student has been able to complete all 10 calibrations as two to five are usually what is normal. While the students must submit these ten reports, this just means that they have to practice what they learned.

The THX program also provides the students with two forms of after class support. The first is a private web site set up for the calibrators to come ask questions about calibration and also find out about service menu codes or talk with TV repairmen or industry experts. They can also go there to research the exam questions. The second form of support is considerably more personal as all students get direct access to the THX instructors if they need that emergency life line.

The THX program also requires that all THX certified video calibrations that the graduating students perform for clients are sent back to THX for a peer review of the calibration work. This work is then either signed off on or rejected and the calibrator has to return to the client to correct the calibration issue. A measure of oversight on a calibration job is nice to have as it can catch errors from someone new to a particular television model. Then again, there are calibrators out there that are not interested in such oversight and would probably want to steer clear of this program.

In practice, the oversight is not nearly as ominous as it might sound. Reports are rarely rejected here since calibrators should know well ahead of time if the report would be rejected or accepted. Quite often it is a careless submission that gets rejected like a person sending in only one page of a four page report. Still, from a client assurance perspective, external oversight is a good selling feature.

Proper calibration equipment is a must for the THX calibrator and the class is designed so that no one can represent themselves as a THX Video Calibrator if they do not buy equipment or have access to the proper equipment. They would not be able to fulfill the 10 calibration requirement then. So if one wants to go down the path to provide THX Video Calibrations to their clients, they have to be prepared to spend an additional $4000 at the very least to get software, a spectroradiometer and a signal generator. Of course $4000 is just the starting point.

And like all precision instruments, the devices need to be checked for continued accuracy every few years so the THX program has a random audit system for their calibrators. But never as scary as it sounds, the recheck system could be as simple as bringing their equipment into another THX class after hours and checking it against the class reference devices. The system is not meant to be a money generator for the hardware vendors on this end. Why spend $300 to send a device in to be rechecked if there really is nothing wrong with it; hence the open invitation to all attendees to come back when possible.